DMT manufactures OEM wear parts and components for a wide range of industries using a comprehensive range of alloys and processes to combat wear in the most aggressive environments – corrosion, abrasion, heat, oxidation, erosion, galling and thermal shock; is usually a combination of 2 and more wear phenomenon. These parts can easily be integrated into a complete new machine offered by the OEM and also be available as spare parts or ungraded parts. The vast majority of our wear parts are critical parts in production that are subjected to wear, where OEM needs optimal wear solution. Our wear parts and components are supplied either as coated, fabricated, cast, rough machined or finished machine parts.

Our expertise in engineering complex solutions to customers “ wear problems “ provides our customers with a technical partner enabling them to produce products with competitive advantage in their own market places because they more cost effective and last longer. Hence many customers have already made DMT their choice to develop special parts for them on a regular basis.

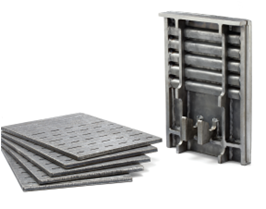

Following are some typical parts developed and supply to the industries:

-Up to 100ton casting facility

-Clinker cooler wear plates for cement plant

-Blow bar and hammers for cement plant

-Casting part for cement plant & quarry

-Wear protection kit for mining excavator

-Cast components for petrol chemical plant

-Coated parts for extreme chemical corrosion